INDUSTRIES & APPLICATIONS

- Home

- Application

- Data Center

Data Center Insulation Solutions

For years, ITW Formex has partnered with top innovators in the data center industry, understanding that customers seek smarter, faster, and more cost-efficient solutions without compromising on quality and safety. Through close design collaboration, our experienced engineering team works hand-in-hand with clients to consistently deliver optimal results.

Product Features and Benefits

Superior Dielectric Strength

Our materials provide excellent electrical insulation, essential for high-voltage EV applications.

Flame Retardance

ITW Formex products meet UL 94 V-0 standards, ensuring high levels of safety.

Moisture and Chemical Resistance

These properties make our products durable and suitable for various environments.

Application Versatility

ITW Formex materials are versatile and can be used in numerous data center components:

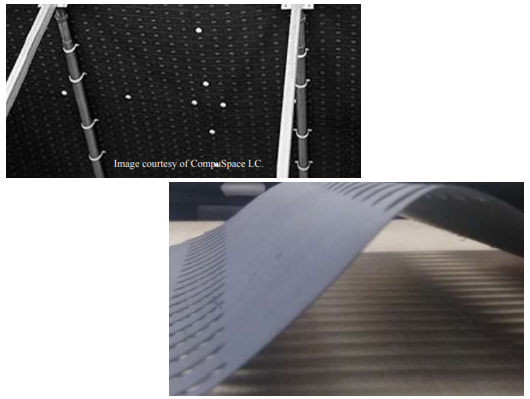

- Cable Tray Liner: Blocks unsightly views of overhead cables, pre-fabricated cut slots allow for easy velcro fastening.

- Air Baffle: Flexible and scalable raised floor partition system solves dymanic thermal imbalances in data centers by directing or blocking airflow under raised floors.

- Blanking Panels: Blanking Panels enable servers to operate at a cooler temperature by filling unoccupied rack space to control bypass airflow.

- Electronics: Power Distribution Units (PDUs) and Uninterrupted Power Supplies (UPSs) are essential for modern data centers, ensuring reliable operation under both normal and emergency conditions. Formex adds an extra layer of protection by isolating other equipment from these critical power devices.

Design Flexibility and Cost Efficiency:

Our materials allow for easy fabrication into complex shapes and 3D forms, contributing to significant cost savings in manufacturing and assembly processes.

Industry Adoption:

Leading global data centers trust ITW Formex for their insulation needs, highlighting our reputation as a reliable supplier of high-performance solutions.

Environmental and Safety Compliance:

ITW Formex materials comply with various environmental and safety standards, including RoHS and REACH, ensuring they meet stringent regulatory requirements.

- Examples of Applications:

- Cable management

- Thermal management

- Isulation solutions

- Examples of Products:

- Formex™ GK: Known for its exceptional dielectric properties and flame retardance.

- Custom Solutions: Tailored to meet specific customer requirements for unique applications.